Global Supply Chains: What They Are and Why They Matter

Ever wonder how a race‑car tyre gets from a factory in Asia to a pit stop in Silverstone? That journey is part of a global supply chain – a network of factories, ports, trucks, and warehouses that moves goods across borders. In motorsport, a broken link can mean a delayed race, and in your kitchen it can mean empty shelves. Understanding the basics helps you see why news about shipping delays or trade wars hits the headlines.

Key Challenges in Today’s Supply Networks

First up, speed vs. cost. Teams always want the fastest parts, but faster often means more expensive air freight or tighter production schedules. When a factory slows down, the whole chain feels the strain. Second, political risk. Tariffs, Brexit‑style border changes, or sudden export bans can add unexpected fees or force companies to reroute shipments. Third, natural events – hurricanes, floods, even pandemics – can shut down ports or factories overnight. The recent Hurricane Erin that battered Cape Verde showed how quickly a storm can turn a smooth route into a bottleneck.

Fourth, technology gaps. Some suppliers still run on paper, which makes tracking shipments a nightmare. Finally, inventory decisions. Carry too much stock and you waste money; carry too little and you risk a stock‑out. Motorsports teams walk this line daily when they order high‑performance components that have long lead times.

Tips for Strengthening Your Supply Chain

Want to make your supply chain tougher? Start by diversifying sources. Instead of relying on a single factory, look for backup suppliers in different regions. If one gets hit by a strike or a natural disaster, you’ve got a fallback.

Next, invest in real‑time visibility. Modern tracking software lets you see where a container is at any moment, so you can react before a delay becomes a crisis. Even small teams can use cloud‑based tools that give alerts on temperature, location, and estimated arrival.

Third, build stronger relationships with logistics partners. A good freight forwarder will push your cargo ahead of the queue when ports get crowded. Regular check‑ins with them keep you informed about any regulatory changes that could affect customs clearance.

Finally, keep a modest safety stock of critical items. For a racing team, that might mean a few extra sets of brake pads or a backup ECU. For a retailer, it could be a handful of best‑selling products. The goal isn’t to over‑stock, but to have a cushion that protects you from short‑term shocks.

By understanding the moving parts of global supply chains and taking simple steps to protect against disruptions, you can keep your projects – whether a high‑speed race car or a weekend grocery run – on track. The world is more connected than ever, and a little foresight goes a long way in keeping everything moving smoothly.

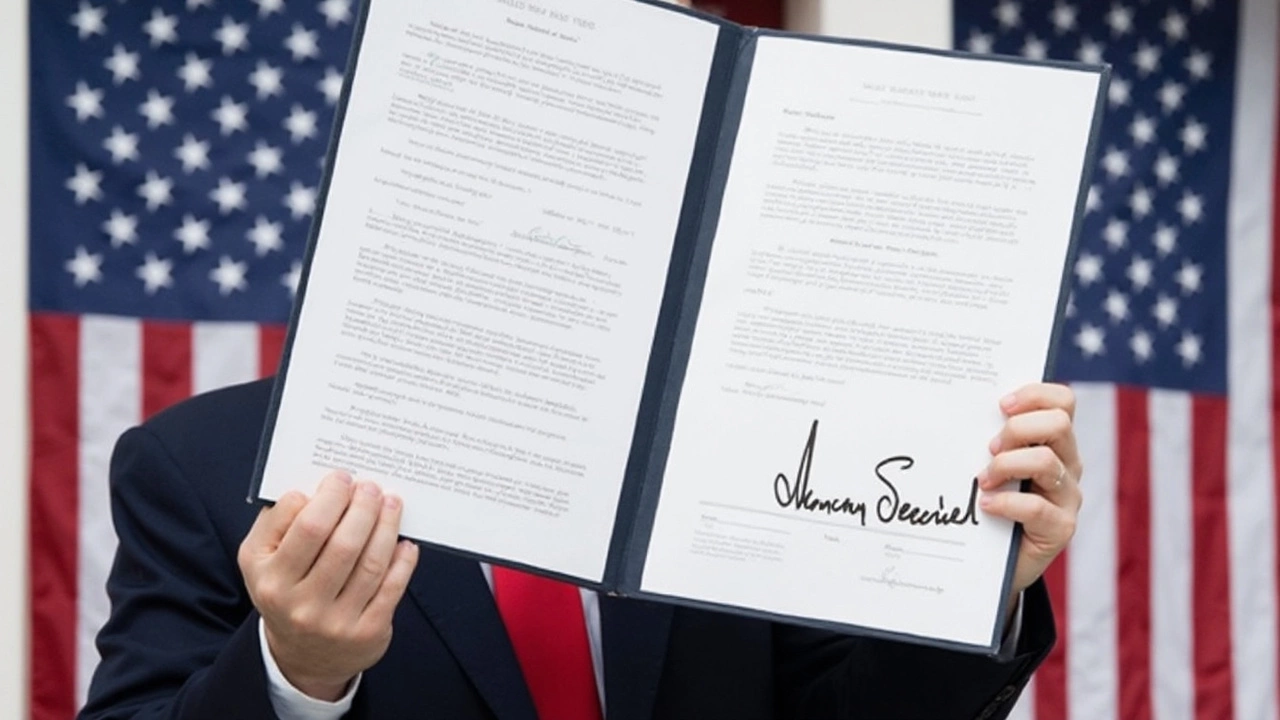

Trump's New Tariffs Shake Global Markets, Spark Debate Over US Trade Strategy

Posted by Daxton LeMans On 8 Apr, 2025 Comments (0)

President Donald Trump has introduced 10% tariffs on 190 countries, with a notable 20% for the EU, aiming to fix trade deficits. While intended to rebuild US manufacturing, these measures have caused significant global market disruptions and invited criticism for potential economic instability. Critics question the tariffs' logic, citing risks to US workers, and highlight potential issues if geopolitical tensions over Taiwan's semiconductors escalate.